Why Perfect Paver Co Takes the Harder Route to Give You Better Results

If you’ve spent any time researching paver sealing in Florida, you’ve probably noticed something strange:

Most companies say polymeric sand doesn’t work in Florida.

They’ll mention the humidity.

They’ll talk about our weather.

They’ll say the sand “never sets.”

And if you don’t work in the paver world, that argument sounds believable.

But here’s the truth:

Polymeric sand absolutely does work in Florida — when it’s used correctly.

And Perfect Paver Co has successfully installed thousands of polymeric sand jobs across the state every year since 2016.

So why is almost every other company telling homeowners the opposite?

Let’s break it down in a clear, simple way.

A Quick Backstory: Why Florida’s Message About Polymeric Sand Is So Different

Before Perfect Paver Co became the largest paver restoration company in Florida, we were paver installers—and not small installs either. Our team has built everything from high-end residential patios to million-dollar commercial projects. Many of us are ICPI-certified, and we understand the engineering behind a paver system from the ground up.

That matters, because in order to restore pavers correctly, you have to understand how the system is designed to work in the first place.

So when we explain the difference between polymeric sand and joint stabilizing sealer, we’re not repeating something we read online. This is our world.

And what we’ve watched happen in Florida over the past decade is… interesting.

How the “One-Day Paver Sealing” Industry Was Born (And Why Polymeric Sand Got Pushed Out)

About 7–8 years ago, a Florida sealer manufacturer introduced a new idea:

“Clean the pavers, sweep in some sand, and seal everything in one day.”

It sounded great to contractors:

- No need to return the next day

- No waiting for the pavers to dry

- No two-day process

- More jobs per week = more money

Pressure washing companies loved it.

Newer sealing companies loved it.

It became the new trend.

But there was a problem:

You cannot properly use polymeric sand in an all-in-one-day process.

Polymeric sand requires:

- Cleaning – Day 1

- Drying – Day 1

- Installation – Day 2

- Activation – Day 2

- Then sealing – Day 2

Meaning: two separate days.

So instead of telling homeowners,

“We don’t want to do a two-day job,”

contractors began repeating a different line:

“Polymeric sand doesn’t work in Florida because of the humidity.”

That message spread everywhere — contractor forums, Facebook groups, pressure washing trainings, you name it.

And suddenly, Florida became the only state in the U.S. where polymeric sand was “bad.”

Follow the Money — You’ll Find the Real Reason

If you trace the messaging back to the source, here’s what you discover:

1. Joint stabilizing sealer is manufactured in Florida.

2. Polymeric sand is not manufactured in Florida.

Florida’s natural sand is too fine to use as the base material, so manufacturers don’t make polymeric sand here.

3. Polymeric sand has to be trucked into Florida from out of state.

This means contractors pay more per bag — sometimes significantly more — because freight costs are built into the price. So for them, choosing polymeric sand isn’t just more work… it’s also more expensive. Using joint stabilizing sealer is cheaper, faster, and more profitable.

4. Polymeric sand reduces how much sealer contractors have to buy and apply.

If a company fills your joints with polymeric sand, you don’t need gallons and gallons of stabilizing sealer.

5. Two-day jobs reduce contractor volume.

Most companies in Florida want to do 2–3 jobs a day.

Perfect Paver chooses quality over volume.

Others choose the opposite.

Put all that together, and it’s pretty easy to see what happened:

Contractors and manufacturers make more money when polymeric sand isn’t used.

So the message became:

“Don’t use polymeric sand in Florida.”

Not because it’s true — because it’s profitable.

Okay… But Let’s Talk About Performance. What Actually Works Better?

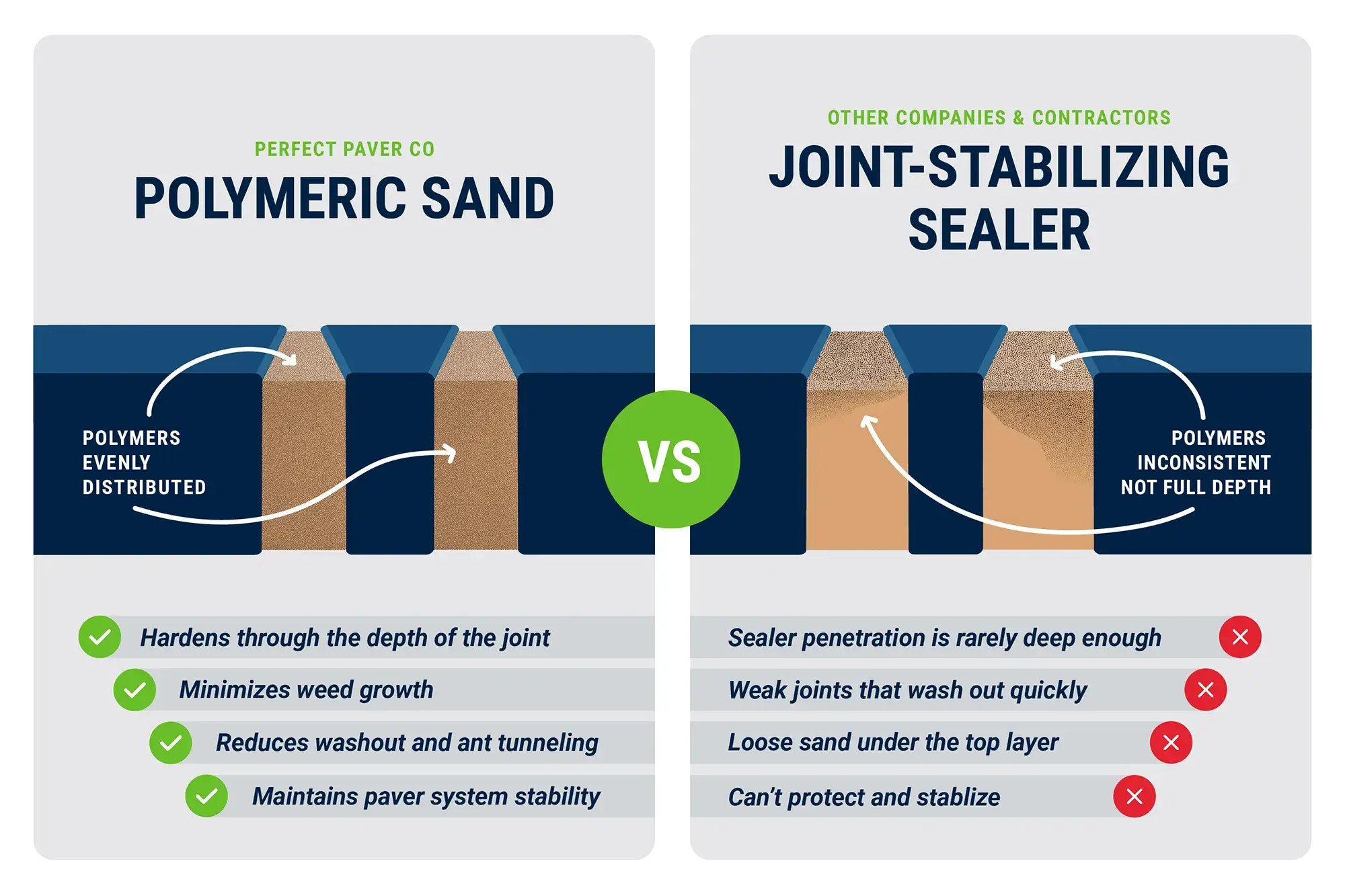

Let’s compare the two materials in simple, visual terms.

Polymeric Sand: Reliable, Consistent, Engineered

What it is:

Natural sand blended with polymers in a controlled manufacturing environment.

What it does:

When we install polymeric sand correctly (after full drying), it hardens all the way through the depth of the joint.

Top to bottom.

Front to back.

Consistent every time.

Why it matters:

You get a joint that:

- Helps minimize weed growth

- Helps reduce washout

- Helps reduce ants tunneling

- Helps maintain the stability of the paver system

And because it’s engineered in a factory, not mixed on the job, the performance is predictable and uniform.

Joint Stabilizing Sealer: Inconsistent, Contractor-Dependent

Here’s what most Florida contractors do:

- Clean the pavers

- Sweep some loose sand back into the joints

- Spray a joint stabilizing sealer

- Hope the sealer penetrates deep enough to harden the sand

And that’s where the problems begin.

Problem 1: Sealer penetration is rarely deep

If a contractor under-applies sealer (which happens often because sealer is expensive), you might get:

- Hardening in the top ¼ inch

- Loose sand under that

- Weak joints that wash out quickly

Homeowners have no way to know how deeply it penetrated.

Problem 2: Joint widths vary

Narrow joints require less sealer.

Wide joints require more.

Most contractors spray the same amount across the entire surface.

That means:

- Some joints don’t get enough

- Some areas get too much

- And that leads to over-sealing problems on the paver surface

Problem 3: Surface sealing and joint stabilization require different amounts of product

This is the biggest contradiction:

- Some pavers can’t absorb heavy sealer without fogging or whitening

- But heavy sealer is exactly what’s needed to stabilize a joint

So contractors are forced into a choice:

Protect the pavers correctly?

or

Stabilize the joints correctly?

You can’t do both consistently with the same product.

Why Perfect Paver Co Uses the Two-Day Process

We could make more money if we switched to the one-day system.

But we don’t — because it delays problems, it doesn’t solve them.

Our Process: Built the Right Way

- Steam clean the pavers

- Let the pavers fully dry

- Install polymeric sand

- Let it set properly

- Seal the pavers the next day

It’s slower, more labor-intensive, and more expensive for us…

…but it’s the right way to restore a paver system.

It’s also why:

- We have hundreds of reviews

- All of them are about paver restoration only

- And the results speak for themselves

We’re not a pressure washing company trying to add a service.

We are paver specialists who take pride in the craft.

So… Does Polymeric Sand Work in Florida?

Yes.

Absolutely.

Without question.

Perfect Paver Co has the track record, the experience, and the engineering background to prove it.

The only reason other contractors dismiss polymeric sand is because it doesn’t fit their business model — not because it doesn’t work.

Final Thought

As a homeowner, you’re trusting someone with your outdoor living space — an area that often represents a major investment.

You deserve the method that delivers the best long-term performance, not the method that delivers the fastest paycheck to a contractor.

If you want it done correctly, consistently, and backed by proven results…

That’s what we’re here for.